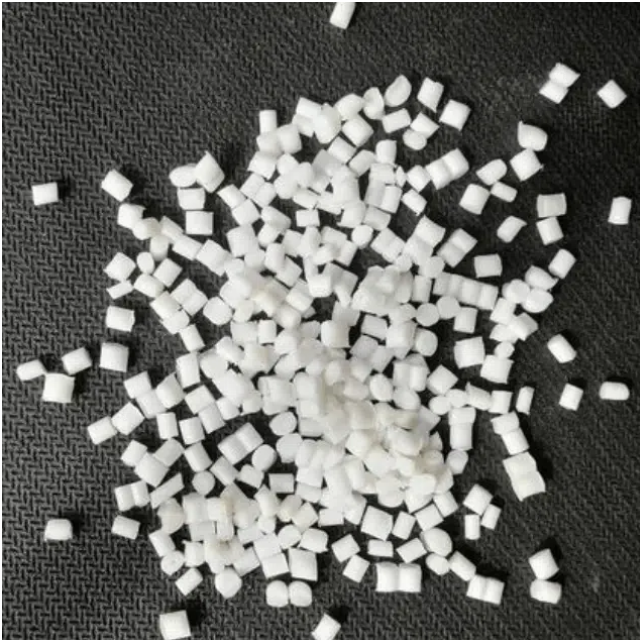

Low-Density Polyethylene (LDPE) has become a preferred material in the medical industry, particularly for applications involving injection bottles and ampoules. Known for its flexibility, clarity, and toughness, LDPE is a versatile material that ensures safe and reliable medical packaging. In this article, we’ll explore why LDPE is the ideal choice for medical-grade packaging, particularly in the production of injection bottles and ampoules, and how it meets regulatory standards while enhancing the performance and safety of medical products.

1. What Makes LDPE a Popular Choice for Medical Packaging?

When it comes to medical packaging, choosing the right material is crucial to ensuring both the safety of patients and the effectiveness of the product. Low-Density Polyethylene (LDPE) is a thermoplastic polymer known for its remarkable properties that make it suitable for use in medical injection bottles and ampoules. LDPE’s unique molecular structure offers flexibility, toughness, and clarity, all of which are essential for packaging products that must meet stringent safety and quality standards. It is an ideal material for maintaining sterility, protecting the contents from external contamination, and ensuring easy product visibility. In this article, we will delve into the key features of LDPE and its advantages over other materials commonly used for medical packaging.

2. What Are the Key Properties of LDPE That Make It Ideal for Medical Applications?

Flexibility: How LDPE Can Be Easily Molded into Different Shapes

LDPE's low-density structure allows it to be easily molded into various shapes and sizes, making it highly adaptable for different types of medical packaging. The material’s flexibility ensures that it can accommodate the specific design requirements of injection bottles and ampoules, which often have intricate shapes that require precision molding. This property also allows for the creation of tight, secure seals, ensuring that the contents of medical products remain safely contained and protected.

Clarity: Ensuring Product Visibility for Dosage and Quality

LDPE is known for its high level of clarity, making it an ideal material for medical applications where product visibility is important. In the case of injection bottles and ampoules, clarity is crucial for both dosage accuracy and quality control. Medical professionals need to visually inspect the contents to ensure the right medication or dosage is being administered. LDPE’s transparency allows for easy visual inspection without compromising the integrity of the packaging, ensuring the safe administration of medications.

Toughness: Providing Durability and Resistance to Impacts

Another key property of LDPE is its toughness. The material is highly resistant to impact and breakage, which is particularly important in medical applications where packaging must withstand handling, transportation, and storage conditions. Injection bottles and ampoules made from LDPE are less likely to crack or break upon impact, ensuring the safety of the contents during transit or use. This durability is also essential for preventing contamination, as a compromised container could lead to the introduction of harmful pathogens or particles.

3. How Does LDPE's Molecular Structure Enhance Performance in Injection Bottles?

LDPE's molecular structure plays a critical role in its performance as a medical packaging material. Unlike other forms of polyethylene, LDPE has a highly branched structure, which gives it a lower density and a more flexible, pliable nature. This structure allows LDPE to stretch and conform to the desired shape, making it ideal for applications where airtight seals and secure closures are needed.

Highly Branched Molecular Structure of LDPE

The highly branched molecular structure of LDPE means that the material is less rigid compared to other polyethylene variants like High-Density Polyethylene (HDPE). This flexibility allows LDPE to be easily molded into complex shapes, making it perfect for the production of injection bottles and ampoules. Additionally, this structure allows the material to maintain its strength and resilience despite being flexible.

Effect on the Material's Ability to Conform to Shapes and Stretch

LDPE’s molecular design allows it to stretch without losing its shape, which is essential in medical packaging. This ability to conform to various shapes ensures that the packaging can securely hold the contents, even under stress. For injection bottles, this property is particularly beneficial in creating tight seals that prevent leaks and contamination, while for ampoules, it helps ensure a consistent, uniform product.

Benefits for the Airtight Sealing of Injection Bottles

A key feature of LDPE is its ability to form airtight seals, which is critical for medical packaging. Injection bottles need to be sealed to maintain sterility and prevent contamination. LDPE’s molecular structure helps it create seals that are both secure and reliable, ensuring that the contents of the bottles remain protected throughout their shelf life.

4. Why Is LDPE Preferred for Medical Ampoules Over Other Materials?

When it comes to medical ampoules, LDPE is often preferred over other materials like HDPE or glass. While glass offers certain benefits, such as high resistance to chemical reactions, it is also prone to breaking, which poses a risk to patient safety. LDPE, on the other hand, offers several advantages that make it a better choice for ampoules.

Lightweight and Impact-Resistant Properties of LDPE

One of the primary reasons LDPE is preferred for medical ampoules is its lightweight nature. LDPE is significantly lighter than glass, making it easier to handle, transport, and store. This weight reduction also reduces shipping costs, which is particularly important in large-scale medical packaging and distribution. Furthermore, LDPE’s impact-resistant properties ensure that ampoules made from this material are less likely to break or shatter, reducing the risk of injury or product loss.

Minimization of Breakage Risks and Easy Handling

Glass ampoules, while effective for certain applications, are prone to breaking during handling or transportation. This can lead to both product loss and safety hazards. LDPE’s durability and impact resistance minimize the risk of breakage, ensuring that ampoules arrive at their destination intact and safe for use. The lightweight nature of LDPE also makes it easier for medical professionals to handle and administer medications, further improving the overall user experience.

5. What Are the Regulatory Standards That LDPE Must Meet for Medical Packaging?

When it comes to medical-grade packaging, LDPE must meet stringent regulatory standards to ensure its safety and efficacy. These standards are put in place to protect patients and healthcare professionals from potential risks associated with materials that come into contact with drugs or medical devices.

Overview of Global Regulatory Standards (FDA, USP)

LDPE used in medical applications must comply with global regulatory standards, such as those set by the U.S. Food and Drug Administration (FDA) and the United States Pharmacopeia (USP). These organizations ensure that materials used for medical packaging are safe, non-toxic, and capable of maintaining the integrity of the product inside. LDPE must undergo extensive testing to ensure it meets these standards, including testing for biocompatibility, chemical safety, and durability under various environmental conditions.

Ensuring Biocompatibility and Chemical Safety

LDPE used for medical packaging must be biocompatible, meaning that it will not cause harm or adverse reactions when in contact with the human body. LDPE’s non-reactive nature ensures that it does not leach harmful substances into the contents of injection bottles and ampoules. This makes it a safe choice for medical applications where patient safety is paramount.

Testing and Certifications That LDPE Undergoes for Medical Use

Before LDPE can be used in medical-grade packaging, it must undergo rigorous testing and certification processes. These include tests for purity, chemical composition, and mechanical properties to ensure that the material meets the required standards for medical applications. Only after passing these tests is LDPE certified for use in injection bottles, ampoules, and other medical packaging applications.

6. Conclusion

In conclusion, Low-Density Polyethylene (LDPE) is an ideal material for medical packaging solutions, particularly for injection bottles and ampoules. Its key properties, such as flexibility, clarity, and toughness, make it the perfect choice for ensuring the safety, durability, and reliability of medical products. LDPE’s ability to conform to shapes, form airtight seals, and resist impact makes it superior to other materials, offering both cost and safety benefits. Furthermore, LDPE meets all the necessary regulatory standards for medical use, ensuring that it is safe for both manufacturers and end users. If you are looking for reliable, high-quality medical-grade packaging materials, LDPE is the solution you need.

For more information about our Medical Grade LDPE products, visit our website or contact us directly.