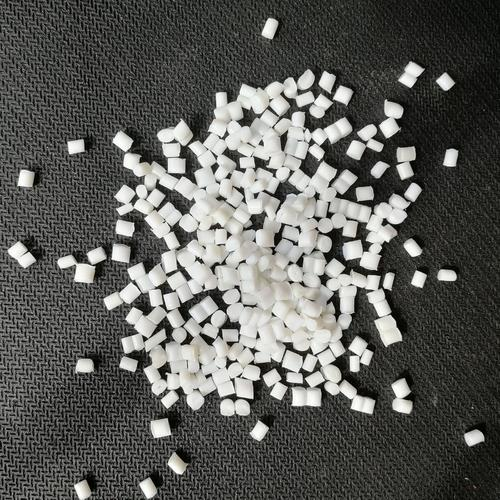

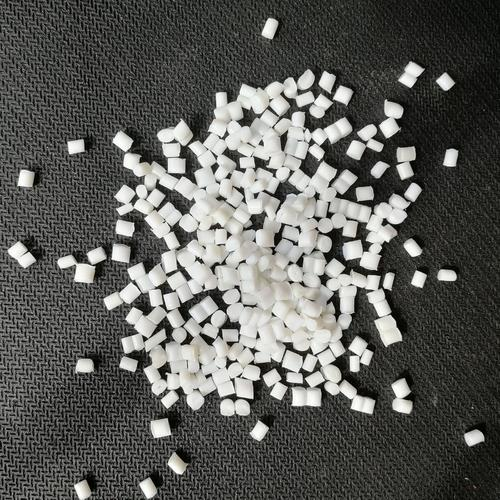

On September 7th, the reporter learned from Daqing Refining & Chemical Company that in order to meet the diversified demand of domestic polypropylene market products, increase the market share of products and constantly innovate product brands, the company has completed the industrial trial production of six brands of new polypropylene products since August.

Among them, polypropylene soft fiber material RP300R is a new product successfully developed according to domestic spunbonded nonwoven sanitary material, which is mainly used in the manufacture of baby diapers, medical surgical gowns and other products. After being put into the market, customers feedback that its index and performance are better than those of foreign products; On the other hand, EP300K, a synthetic resin-based impact copolymer polypropylene product, has high impact resistance and rigidity, and is mainly used to manufacture hollow plates, sheets, crates, coating barrels and other products.

In the early stage of trial production, after determining the optimal scheme, the technicians will send it to the post employees for training and study in advance, so that the post employees can master the key points in operation skillfully and make a good advance for trial production. In the process of brand switching of EP100K products, the leading cadres in the operation area took the lead in sticking to the site, changing the process, starting the unit and adjusting the parameters, checking and handling all kinds of abnormal problems overnight, and the brand switching was successful once.

Since the outbreak of the epidemic in Daqing on August 20th, the cadres and employees of the company have worked together to fight the epidemic and ensure production. By September 7th, a total of 8971.15 tons of polypropylene products were produced.